CRANE ChemPharma & Energy

Brands You Trust

CRANE ChemPharma & Energy (within Crane’s Fluid Handling segment) designs and manufactures a variety of high performance products including: highly engineered check valves, sleeved plug valves, lined valves, process ball valves, high performance butterfly valves, bellows sealed globe valves, aseptic and industrial diaphragm valves, multi/quarter-turn valves, actuation, sight glasses, lined pipe, fittings and air operated diaphragm and peristaltic pumps.

Visit supplier siteFeatured products

Saunders® offers a comprehensive range of diaphragm valves for use in any industry. They encompass the full spectrum of corrosive and abrasive applications that require reliable valve operation. Easily maintained to ensure many years of trouble-free operations, Saunders® diaphragm valves have become a standard in industries such as chemical production, mining, water treatment, fertilizers and marine

Resistoflex® ATL was designed specifically to address the challenges of handling severe service applications. It has been proven to reduce permeation rates by up to 60% and features a full vacuum rating up to 450°F (232°C). As such, ATL Lined Pipes and Fittings are an economical choice compared to Exotic Alloys or Glass Lining.

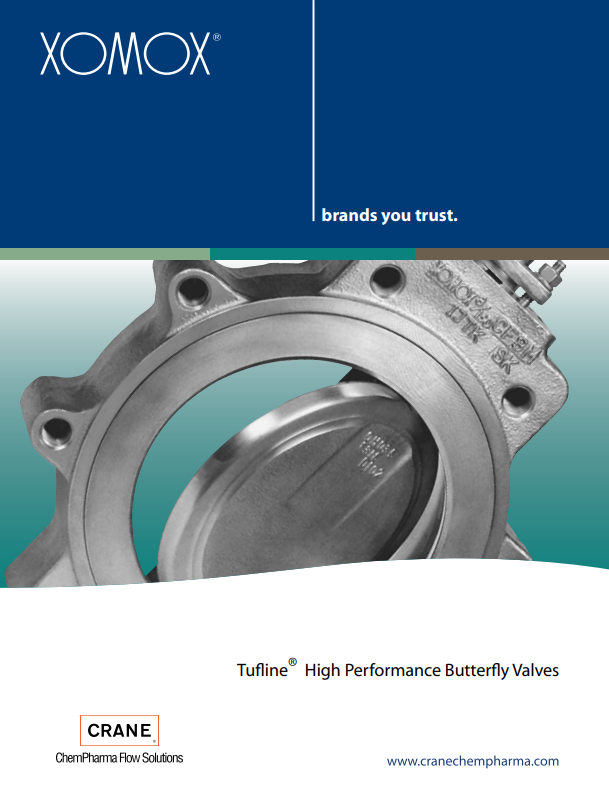

The XOMOX® Series 800 offers a broad range of high performance butterfly valves with long life and extrem tightness under high pressure and vacuum conditions.

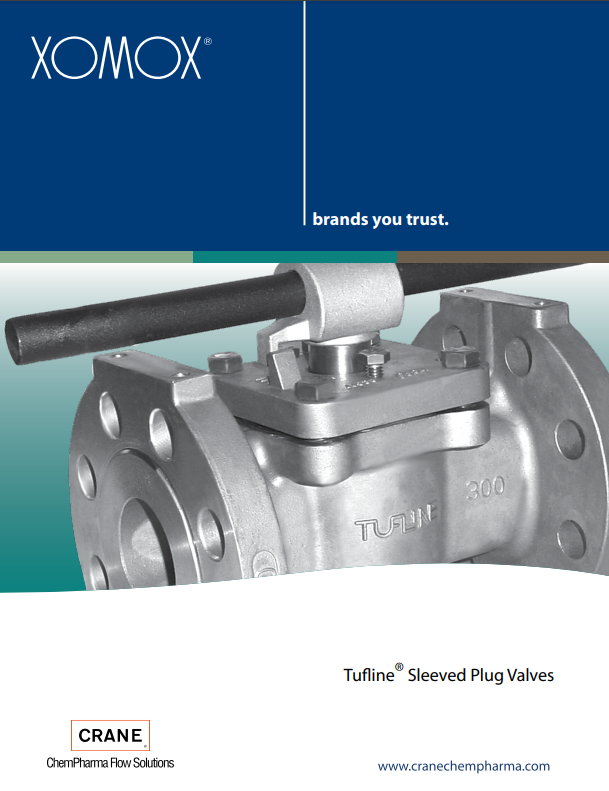

- Design more economical, flexible, and compact fluid handling systems.

Bi-directional flow, simple actuation, lightweight, compact design, and multiport configurations all facilitate improved system design. - Superior, longer-lasting in-line sealing.

The inert PTFE sleeve completely surrounds the plug. The sleeve provides a large, circumferential sealing surface from port to port. Open, closed, or rotating, the seal is assured. No ball or gate valve can match this sealing power. - Secure sealing with no cold-flow, deformation, or rotation of the sleeve.

The sleeve is securely nestled in the valve body. High pressure ribs, top and bottom retention, and 360° port lips all assure sleeve containment. - No seizing. No sticking.

As the plug rotates, the 360° port lips provide a self-cleaning action to remove scaling and adhering media. - No cavities. No contamination.

There are no body cavities where flow media can accumulate and contaminate future processing. This cavity-free design also prevents sticking.

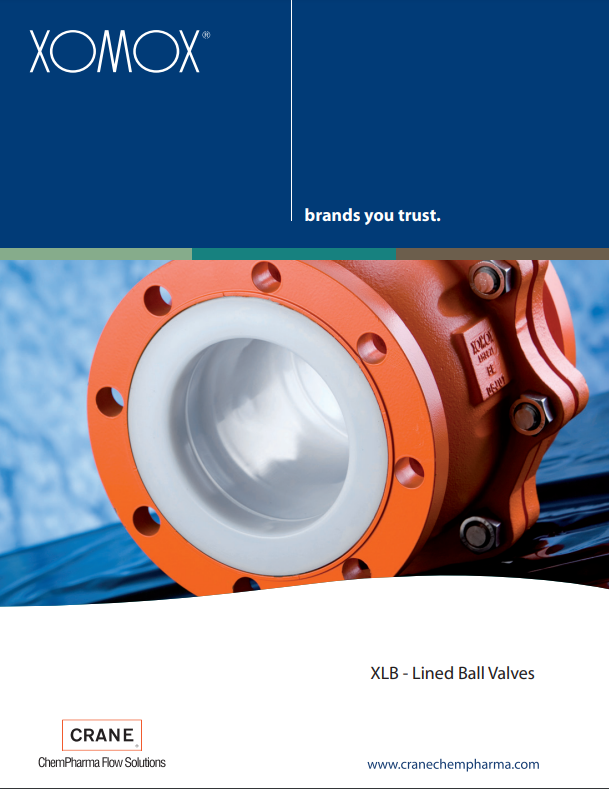

XOMOX® XLB Lined Ball Valves offer economical solutions for the vast majority of chemical applications while maintaining the highest possible degree of performance in terms of in-line leakage and fugitive emissions with the Patented SX stem seal design.

Downloads

Crane – Resistoflex – Design Manual 2018

Download PDF

Crane – Resistoflex ATL PTFE

Download PDF

Crane – Saunders – Industrial Diaphragm Valves 24PG BU EN

Download PDF

Crane – Saunders – Industrial Diaphragm Valves FL EN

Download PDF

Crane – Xomox High Performance Butterfly Valves 30-48inch

Download PDF

Crane – Xomox IOM Manual

Download PDF

Crane – Xomox Tufline® High Performance Butterfly Valves

Download PDF

Crane – Xomox Tufline® Sleeved Plug Valves

Download PDF

Crane – Xomox XLB Lined Ball Valves

Download PDF

Crane ChemPharma and Energy – Overview

Download PDF